About Vitreous Enamelling

Vitreous enamel is a glass coating chemically bonded to steel at high temperatures around 850° celsius.

- The undercoat is sprayed onto steel and fired in a Vitreous Enamelling furnace to form a permanent bond with the steel base.

- The covercoat is applied by either dipping or spraying to obtain a wide range of colours for which Vitreous Enamel is renowned.

- The graphics are screen-printed, a process which allows fine detail and registration.

How is vitreous enamel superior?

Glassmetal Industries are proud to have been manufacturing the finest Vitreous Enamel products for over 100 years.

- When Vitreous Enamel is exposed to ultra violet radiation from the sun it has proven life span of at least four times any other metal finish.

- Vitreous Enamel is vandal-proof—almost impossible to scratch.

- Graffiti can be easily removed with solvent from a rag without any damage to the surface.

- Vitreous Enamel has the hardness of glass and the strength of steel.

- Vitreous Enamelled products can be any shape, size and colour you want.

What is Vitreous Enamel used for?

Vitreous Enamel is odour-free, stain proof, heat resistant and impervious to practically every substance. It therefore has a wide range of uses;

- In the home: baths, washing machines, dishwashers, heaters, fire places, gas and electric cookers, BBQs, clock faces and cookware;

- In places you can't see: hot water services, storage tanks, car exhaust systems, printed circuits and heat exchanges;

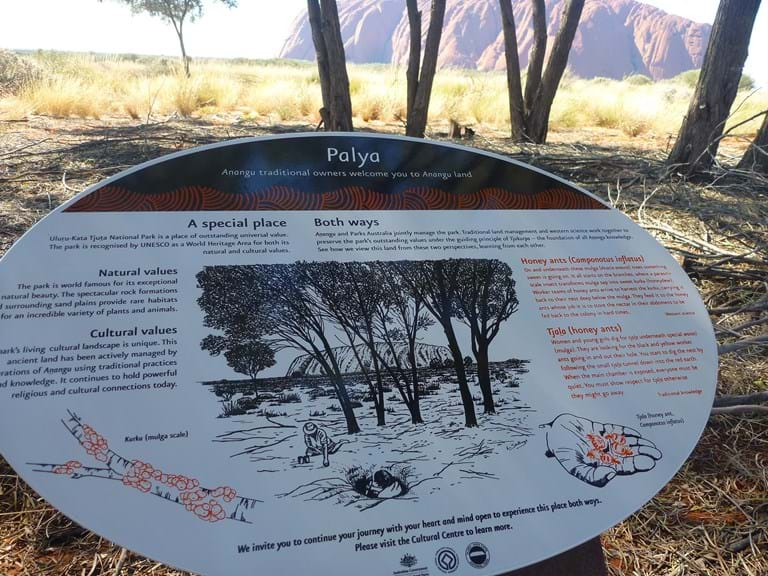

- In places you can see: street signs, railway signs, nostalgia signs and murals;

- In the building industry: interior and exterior architectural panels, fascias, spandrels and partitions.